Understanding the Role of Positive Displacement Pumps in Various Industries

In today's rapidly evolving industrial landscape, the positive displacement pump stands out as a critical component across a variety of sectors, including auto repair, farm equipment repair, and structural engineering. These pumps, known for their reliability and efficiency, play a vital role in enhancing productivity and performance. This article delves deep into the significance of positive displacement pumps, exploring their working mechanisms, benefits, applications, maintenance tips, and much more.

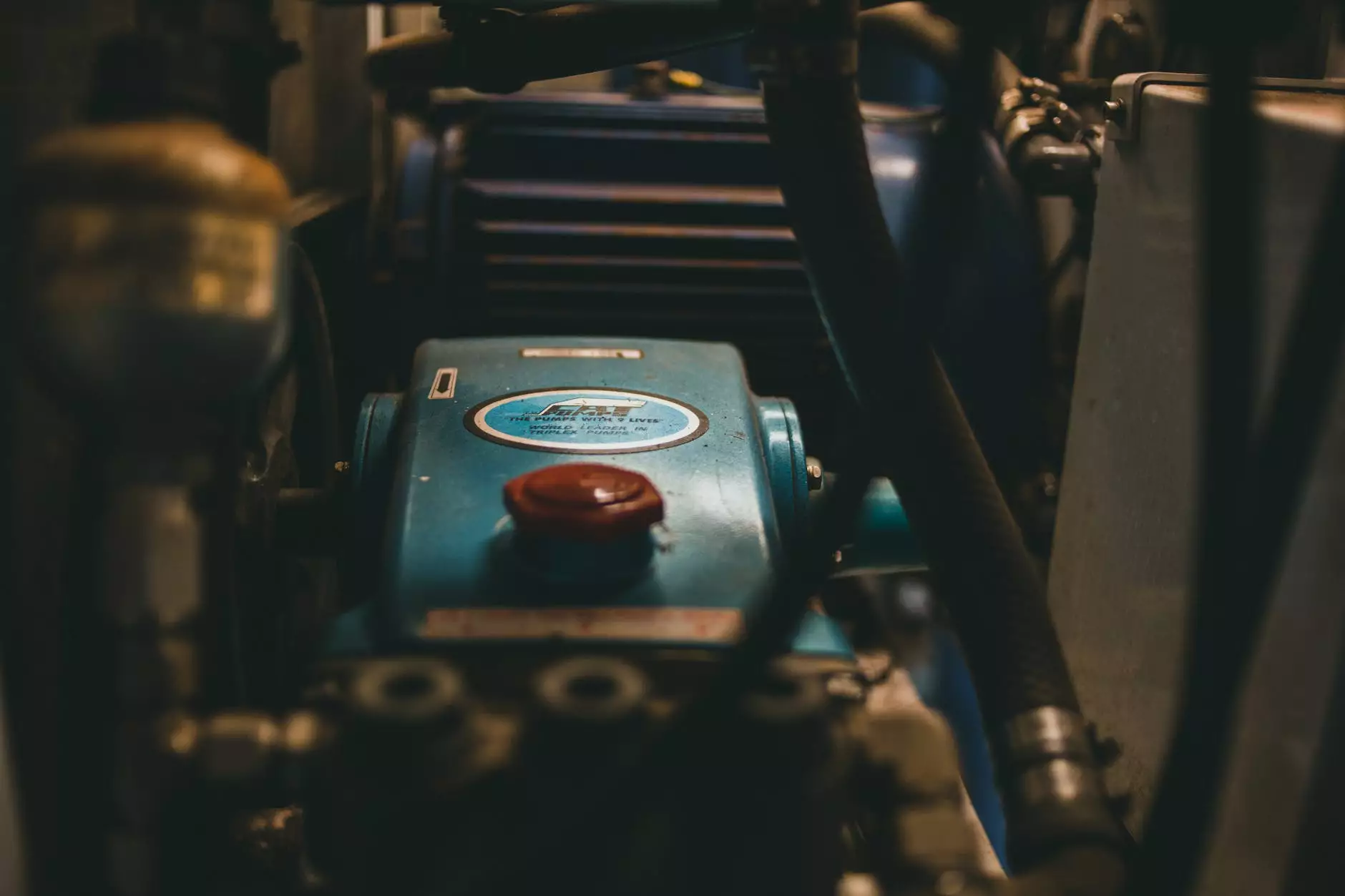

What is a Positive Displacement Pump?

A positive displacement pump is a type of pump that moves fluid by trapping a fixed amount of it and forcing (displacing) that trapped volume into the discharge pipe. Unlike centrifugal pumps, which create flow by converting kinetic energy into pressure, positive displacement pumps rely on a mechanical action to move liquids. This fundamental difference makes them exceptionally suited for various industrial applications.

Types of Positive Displacement Pumps

There are primarily two categories of positive displacement pumps: gear pumps and diaphragm pumps. Each type has unique features that make it ideal for specific applications.

- Gear Pumps: These pumps consist of two gears that rotate to trap and move fluid. They are highly efficient for transferring viscous fluids, making them ideal for applications in the automotive and industrial sectors.

- Diaphragm Pumps: Utilizing a flexible diaphragm, these pumps can handle corrosive and abrasive fluids. They are widely used in environments where contamination is a concern, such as in agricultural settings.

Applications of Positive Displacement Pumps

Positive displacement pumps offer versatile applications across industries. Below are some key sectors that benefit from their use:

1. Auto Repair

In the auto repair industry, positive displacement pumps are essential for various tasks, such as:

- Fluid transfer (transmission fluids, oil changes)

- Fuel dispensing

- Cooling systems

The reliability and precision of these pumps ensure that vehicles operate smoothly and efficiently.

2. Farm Equipment Repair

In agriculture, the efficiency of farm equipment is paramount. Positive displacement pumps contribute significantly by:

- Enhancing irrigation systems

- Transferring fertilizers and pesticides

- Managing liquid waste disposal

These pumps are designed to handle various agricultural liquids, ensuring optimal performance of farming equipment.

3. Structural Engineering

In the realm of structural engineering, the positive displacement pump is vital for:

- Pumping concrete and other viscous materials

- Managing water in excavation sites

- Transferring liquefied gases during construction

Their ability to maintain consistent flow rates makes them indispensable for ensuring structural integrity and safety.

Benefits of Using Positive Displacement Pumps

The utilization of positive displacement pumps comes with a range of advantages:

- High Efficiency: These pumps are capable of moving high-viscosity fluids efficiently without the loss of flow pressure.

- Versatility: They can handle a wide range of fluids, including viscous, corrosive, and shear-sensitive liquids.

- Constant Flow Rate: Unlike centrifugal pumps, positive displacement pumps provide a constant flow irrespective of pressure fluctuations.

- Durability: Built to resist wear and tear, they can operate in challenging environments with ease.

Maintenance Tips for Positive Displacement Pumps

Maintaining your positive displacement pump is crucial for its longevity and performance. Here are some essential maintenance tips:

- Regular Inspection: Conduct routine checks for leaks, vibrations, and unusual noises that may indicate wear or damage.

- Routine Lubrication: Ensure that the pump’s components are well-lubricated to prevent friction damage.

- Monitor Operating Conditions: Keep an eye on pressure and flow rate to ensure they are within the recommended limits.

- Replace Worn Components: Timely replacement of seals, gaskets, and other parts can prevent larger issues down the line.

The Future of Positive Displacement Pumps

As technology continues to advance, positive displacement pumps are evolving as well. Future innovations may focus on:

- Smart Technology: Incorporating IoT solutions for real-time monitoring and data analysis.

- Energy Efficiency: Developing pumps that consume less energy while maintaining performance.

- Environmental Sustainability: Creating pumps that reduce waste and are made from eco-friendly materials.

Conclusion

In conclusion, the significance of positive displacement pumps cannot be overstated in industries such as auto repair, farm equipment repair, and structural engineering. Their unique design offers numerous advantages, including efficiency, versatility, and reliability. By understanding their operation, benefits, and maintenance, businesses can enhance their productivity and ensure the longevity of their operations. Investing in quality positive displacement pumps is not merely an operational decision—it’s a commitment to excellence and efficiency in every aspect of your work.